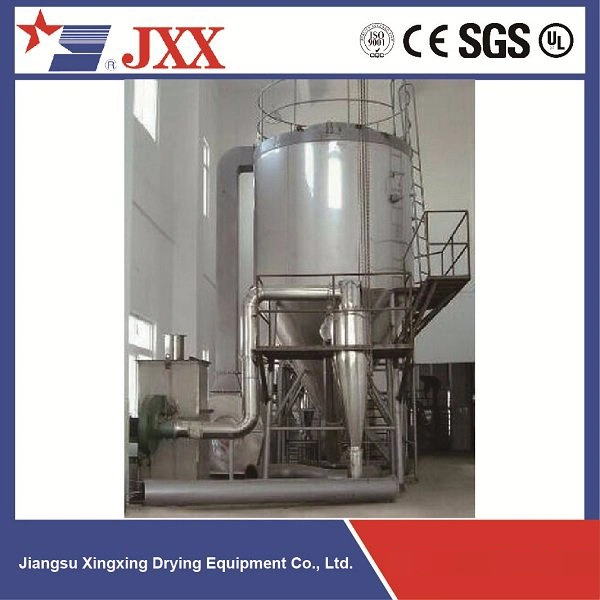

スプレー乾燥機 PAC、Ab、ABS ラテックス、尿素樹脂、フェノール樹脂、濃厚接着剤 (尿素) ホルムアルデヒド樹脂、ポリエチレン用スプレー乾燥機

会社紹介:Jiangsu Xingxing Drying Equipment Co., Ltd 説明 スプレー乾燥は、液体成形プロセスおよび乾燥業界で最も広く使用されている技術です。 粉体の製造に最適です

基本情報

| モデル番号。 | LPG-25 |

| 熱源 | 電気、蒸気、石炭ガス、天然ガス、燃料 |

| タイプ | 遠心スプレー |

| 操作方法 | 継続的 |

| 構造 | 噴霧乾燥機 |

| 乾燥媒体 | 空気 |

| 出口空気温度 | 80~90℃ |

| ドライパウダーのリサイクル率 | 95% |

| 吸気温度 | 140~350℃ |

| 輸送パッケージ | 木製パッケージ |

| 仕様 | 7000*3000*6000 |

| 商標 | JXX |

| 起源 | 中国 |

| HSコード | 84339090 |

| 生産能力 | 20セット/月 |

製品説明

会社紹介:江蘇興興乾燥設備有限公司説明

スプレー乾燥は、液体成形プロセスおよび乾燥業界で最も広く使用されている技術です。 溶液、エマルション、固液、ポンプ輸送可能なペースト状態から粉末状および顆粒状の固体製品を製造するのに最適です。 したがって、粒度分布、残留水分含有量、嵩密度、および粒子の形状が精度基準を満たす必要がある場合、噴霧乾燥は理想的な選択です。

動作原理

濾過され加熱された空気は乾燥機上部の空気分配器に入り、らせん状に均一に乾燥室に入ります。 液体は塔頂部の高速遠心噴霧器を通過(回転)して極めて細かいミスト状の液体ビーズとして噴霧され、熱風と並流接触することで短時間で完全に乾燥させることができます。 最終製品は乾燥塔とサイクロン分離器の底部から連続的に排出され、排ガスはファンによって排出されます。

Company ShowCompany introduction: Jiangsu Xingxing Drying Equipment Co., Ltd.Jiangsu Xingxing Drying Equipment Co.,Ltd has established in 1998 and it covers an area of 15000 square meters, possesses fixed asset of USD 7 million. The products have exported to US, Singapore, India, Ukraine, Russia, Korea and so on. The company have advanced production equipment , excellent technical team and after-sales service.CERTIFICATEPackage:wooden caseService:pre-sale serviceWe Invite customers to visit our company and communicate on technical requirements face to face.sale serviceResponsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.after-sale serviceWe provide installation, debugging, maintenance, training and other services; Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline, and arrange personnel to visit customers every year to know more customer needs,like customer operation problems in the process of production equipment.quality promiseOur company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality.Equipment operation safe reliable, affordable, easy to maintain.Equipment warranty period is one year,all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage,the company for free maintenance or replacement.We look forward to cooperating with partners from all over the world to build win-win cooperation relationship in long term. Welcome for your visiting.Previous ExhibitionFAQ:1. Q: Please describe your warranty period. A: 15 months after the equipment is arrived at the destination port or 12 months after the installation and commissioning of the equipment, whichever comes first.2. Q: Do you provide on-site installation and commissioning? A: Yes, we do. If on request, we'll provide the guidance of on-site installation and commissioning. Usually one mechanical engineer and one electrical engineer to assist.3. Q: How about the cost of on-site installation and commissioning guidance? A: The cost consists of round-trip air tickets, room and board expenses, service cost (labor cost), and site transportation (or directly provided by client), which shall be paid additionally.4. Q: Are you a factory or a trading company? A: We are a professional manufacturer. We have own factory and pilot plant for customers to do sample testing.